DAG’s Method

Feasability Analisys

Dag’s team defines the aim of the project and the business areas involved.

Material Choice

We cooperate with our compounders to the development of mixes recipes according to international standards and customer’ specifications.

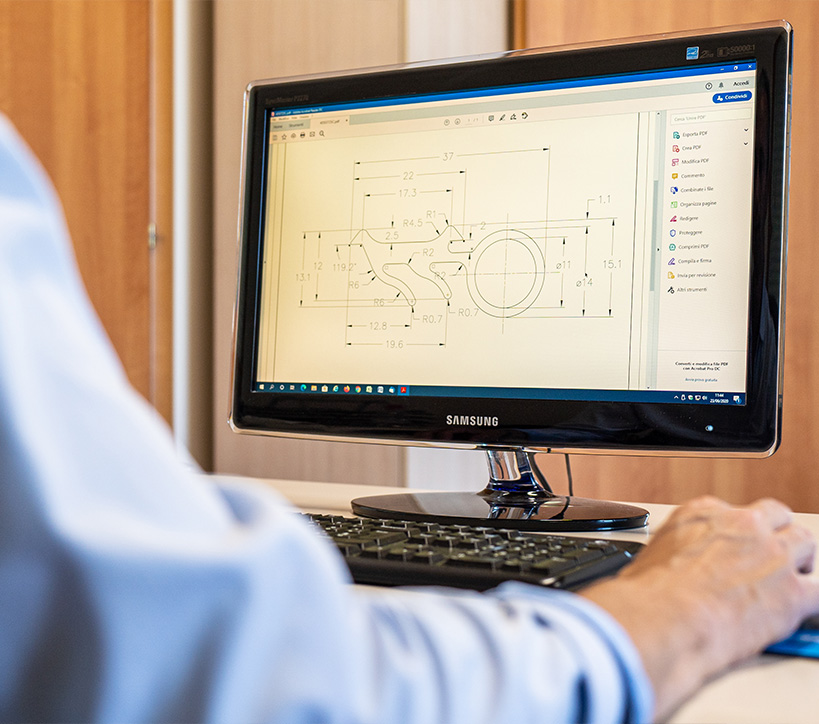

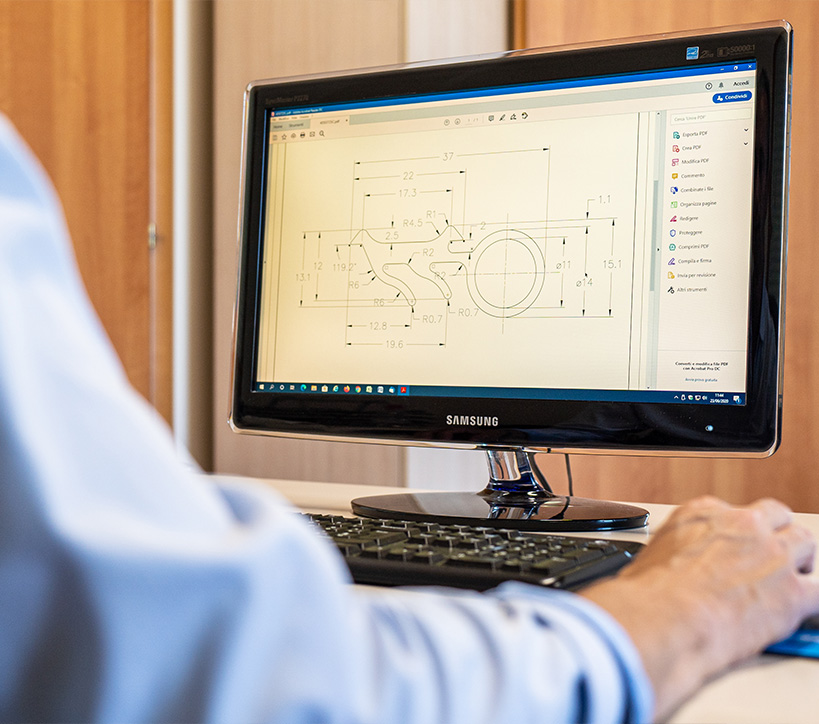

Co-Design

We take part to the mould’s design, involving professional figures with different skills and different operate levels.

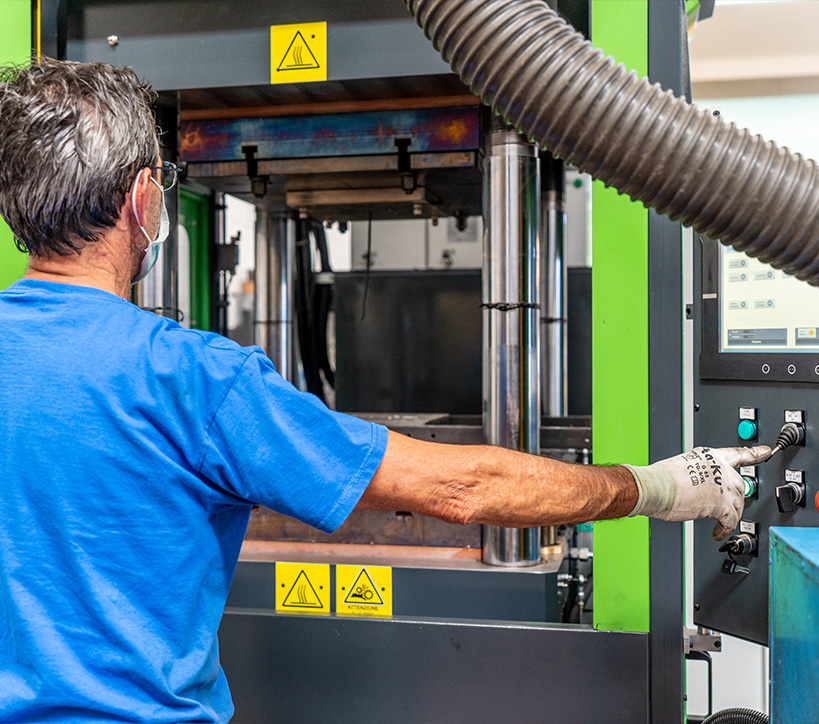

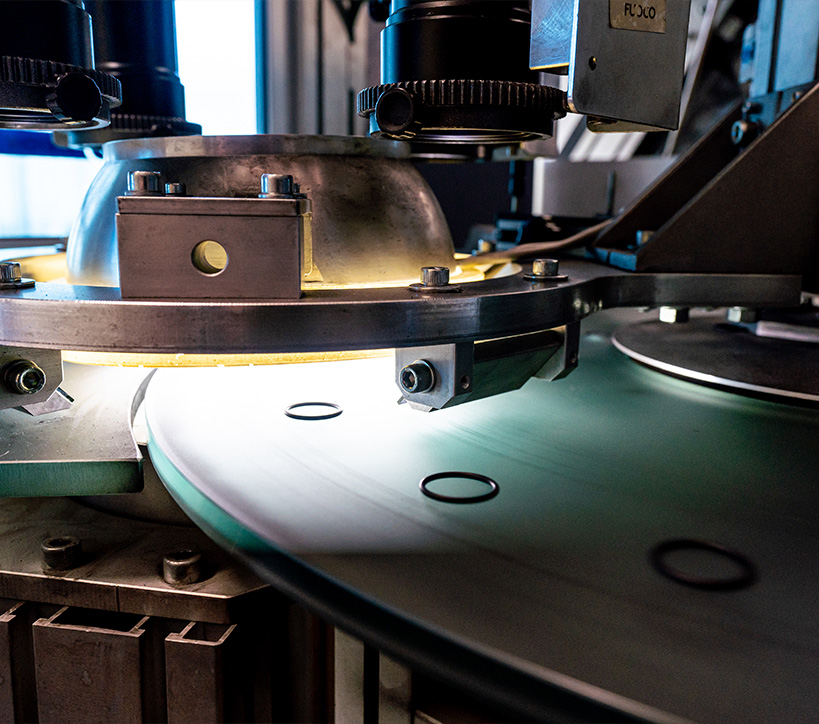

Machinery fleet

We are provided with vertical and horizontal moulding machine for the rubber and silicone and compression of O-rings, washers and small and medium-sized technical parts, in small series or in large lots.

Manual Sorting

The manual sorting department consist in three workstations equipped with lighting systems and magnifying lenses that guarantee an optimal vision to see imperfections.

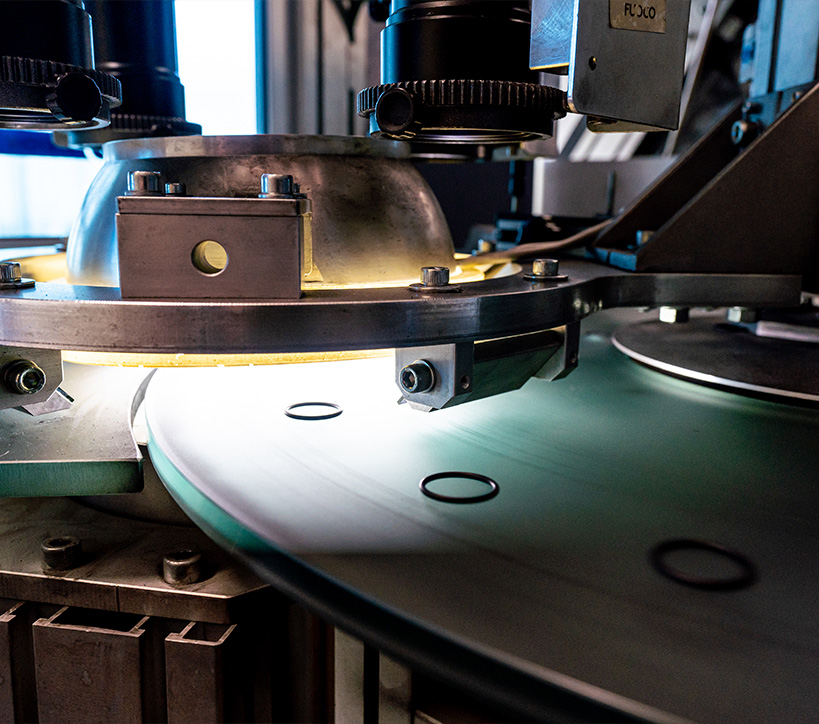

Authomatic Sorting

The authomatic sorting department is formed by a sorting machine equipped with cameras that inspect the total area of the items, parting the ones to trim from the compliant ones.

Laboratory

Our laboratory has measuring devices and control instruments that are necessary to qualify the requirements for the costumer’s products.

Quality

The control activity and the documents that ensure the product’s compliance are lead by qualified personnel.

Delivery

Our national delivery service with courier provides the use of the better transportation with collection and delivery within a maximum of 24 working hours.